1.SiC's Advantages in Green Energy Applications

The wide bandgap of SiC (Silicon Carbide), which is over three times wider than that of conventional Si (Silicon), allows it to withstand voltages over ten times greater. SiC's low loss and high-power characteristics are suitable for applications requiring high voltage and large currents. These applications include electric vehicles, electric vehicle charging infrastructure, solar energy systems, and offshore wind power generation equipment, among other green energy generation devices. Compared to traditional Si (Silicon), third-generation semiconductor material SiC can reduce energy conversion losses by 50% and lower power conversion costs by 20%, while also improving the range of electric vehicles by 4%.

2.SiC's Role in the Emerging Era of High-Voltage Battery Systems

Currently, electric vehicles primarily use battery power systems ranging from 200V to 450V, while higher-end models are advancing towards 800V battery power systems. There is a significant market demand for extending battery range, increasing battery capacity, and reducing charging times. Batteries are evolving towards high-voltage 800V systems, which places high expectations on SiC's ability to withstand these higher voltages. According to STMicroelectronics' observations, any battery power system operating at 800V will be a market for SiC.

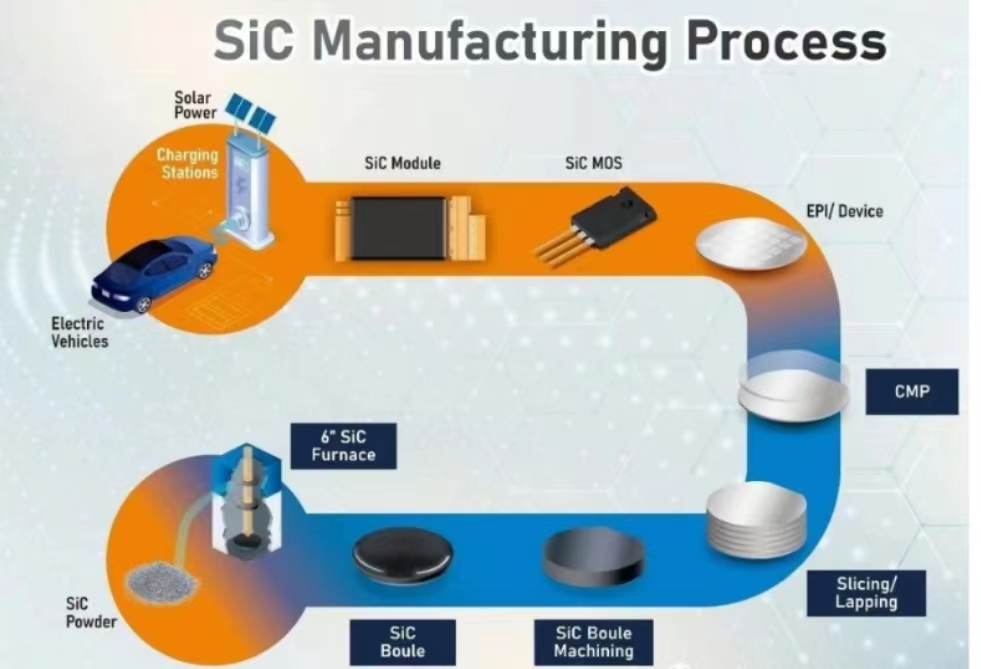

3.The Lifecycle of Silicon Carbide Wafers: From Production to Application

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...

With the continuous advancement of power electronics, RF devices, and optoelectronic technologies, the demand ...

The selection of substrate materials plays a crucial role in the development of high-frequency, high-power RF ...