Silicon Carbide Epitaxial Wafer Fabrication Methods

CVD method is currently the most widely used technique for silicon carbide (SiC) epitaxial wafer fabrication.

1.Epitaxy is a common technique for producing single crystal thin films. It differs from S-device processes, and almost all SC power electronic device processes are implemented on 4H-SiC homoepitaxial layers. The substrate mainly serves a supportive and conductive role. Currently, methods for SiC thin film epitaxy primarily include Chemical Vapor Deposition (CVD), Molecular Beam Epitaxy (MBE), Liquid Phase Epitaxy (LPE), Pulsed Laser Deposition (PLD), etc.

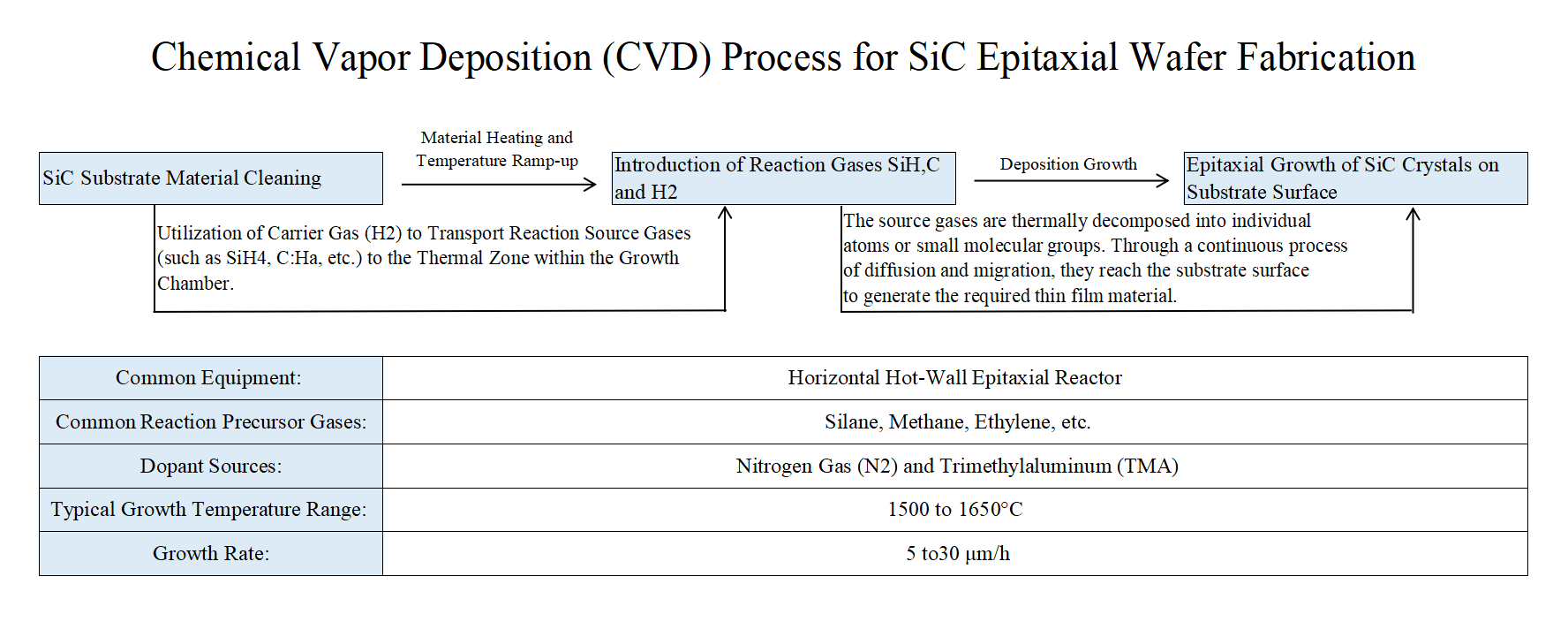

2.Chemical Vapor Deposition (CVD) is the most popular method for 4H-SiC epitaxy. Its advantages lie in the effective control of gas source flow rates, reaction chamber temperature, and pressure during the growth process, which significantly reduces random factors in the epitaxial process and ensures process stability. By adjusting the flow rates of various gases during the epitaxial process, the thickness, doping concentration, and doping type of the epitaxial layer can be precisely controlled, demonstrating strong process controllability. Guangdong Tianyu employs the CVD method to produce SiC epitaxial wafers and possesses the largest number of SiC epitaxial furnaces using the CVD method in China.

3.Comparing Liquid Phase Epitaxy (LPE), Molecular Beam Epitaxy (MBE), and Chemical Vapor Deposition (CVD), MBE produces the highest-quality SiC epitaxial layers with the fewest defects. However, its growth rate is relatively slow. Considering industrial production, MBE and LPE have slower growth rates and cannot meet industrial demands. In contrast, CVD offers a higher growth rate, meeting the necessary conditions. Additionally, CVD can directly fabricate complex semiconductor devices, and CVD systems are relatively simple to operate with lower costs.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...