With the continuous advancement of power electronics, RF devices, and optoelectronic technologies, the demand for high-performance semiconductor materials is increasing. Silicon carbide (SiC), with its superior physical and electrical properties, has become a leading third-generation semiconductor material. Among them, SiC epitaxial wafers excel in high-voltage, high-temperature, and high-frequency applications, making them essential in power electronics and communication fields.

What is a Silicon Carbide Epitaxial Wafer?

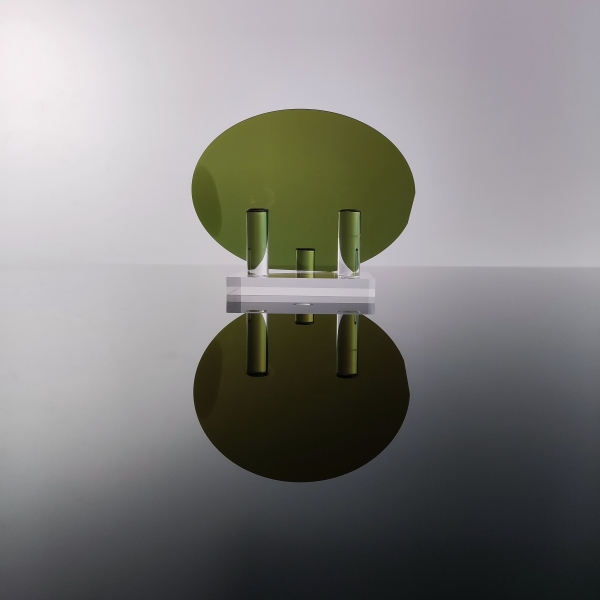

A silicon carbide epitaxial wafer (SiC Epitaxial Wafer) is a thin SiC film grown on a high-quality SiC substrate using a chemical vapor deposition (CVD) process. This homoepitaxial structure can be customized in terms of epitaxial layer thickness, doping concentration, and defect density to meet the technical requirements of various devices.

Key Technical Parameters of SiC Epitaxial Wafers

1. Substrate Types: Available in N-type conductive, P-type conductive, and semi-insulating SiC substrates to meet different application needs.

2. Epitaxial Layer Thickness: Customizable, ranging from hundreds of nanometers to tens of micrometers, with typical thickness uniformity <2%.

3. Doping Concentration: N-type (doped with nitrogen) or P-type (doped with aluminum), ranging from 10¹⁴ cm⁻³ to 10¹⁹ cm⁻³, with concentration uniformity better than ±10%.

4. Defect Control:

Usable area exceeding 95% (based on 2×2 mm² die statistics).

Low defect density, such as BPD (Basal Plane Dislocations) <100 cm⁻² and TSD (Threading Screw Dislocations) <500 cm⁻².

5. Surface Quality: Surface roughness Ra < 0.5 nm, TTV (Total Thickness Variation) < 3 μm, Bow < 10 μm, Warp < 10 μm.

Applications of SiC Epitaxial Wafers

Power Electronic Devices: Used in SiC MOSFETs, SiC SBDs (Schottky Barrier Diodes), IGBTs, and JFETs, widely applied in electric vehicles, photovoltaic inverters, power grids, and railway transportation.

RF and Microwave Devices: High-frequency power amplifiers for 5G base stations, satellite communications, and radar systems.

Optoelectronic Devices: Ultraviolet detectors, laser diodes, LEDs, and more.

High-Temperature and High-Frequency Devices: Aerospace, military, and industrial power applications requiring high reliability.

JXT Technology Provides High-Quality SiC Epitaxial Wafers

JXT Technology offers SiC epitaxial wafers ranging from 2 inches to 8 inches, with customizable epitaxial thickness, doping concentration, and substrate types to meet the strict requirements of the power electronics, RF, and optoelectronics markets. Our SiC epitaxial products feature high uniformity, low defect density, and excellent surface quality, providing a reliable material foundation for next-generation semiconductor devices.

If you require SiC epitaxial wafers, feel free to contact us for detailed technical specifications and customized solutions!

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...