As a third-generation semiconductor material, silicon carbide wafers not only have the advantages of wide band gap, but also have a characteristic of better thermal conductivity. Usually, the electronic components in electric vehicles will generate a lot of heat during operation. If the heat dissipation performance is not good, it will have an impact on the service life and stability of the electric vehicle. Silicon carbide wafers have good thermal conductivity just enough to meet the needs of electric vehicles.

Silicon carbide wafers are usually divided into N type and semi-insulating type, and the thermal conductivity between the two is different, as follows:

1. Thermal Conductivity (4H-N SiC wafer): 3.7-4.2W/cm·K

2.Thermal Conductivity (4H-HPSI SiC wafer): 3.9-4.9W/cm·K

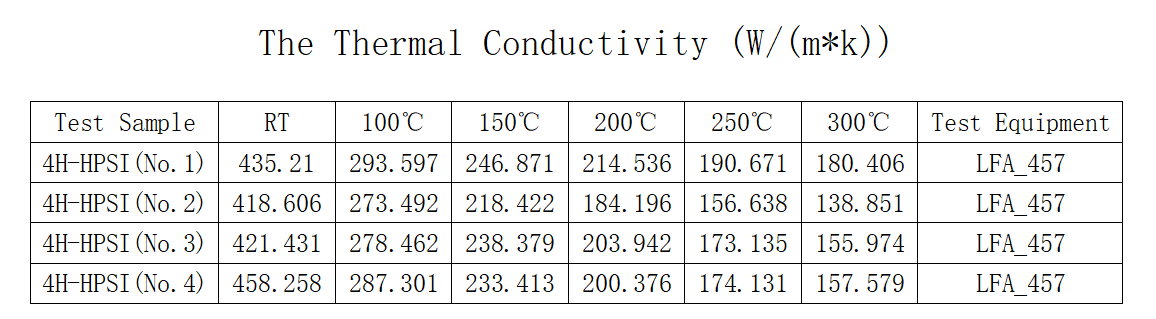

JXT Technology Co., Ltd. (http://www.jxtwafer.com/) tested the thermal conductivity of semi-insulating silicon carbide under different temperature conditions, and obtained the following results:

Through the above data analysis, the thermal conductivity of semi-insulating silicon carbide wafers is better than that of conductive silicon carbide. At present, some developers are using semi-insulating silicon carbide wafers as heat sinks. We will wait and see.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...