In today's field of microelectronics and nanotechnology, silicon carbide wafers (SiC wafers) serves as a widely used material with significant potential in high-power electronic devices, optoelectronic devices, and sensors. In the fabrication and device processing of SiC wafers, etching technology plays a crucial role. This article explores the importance and applications of etching in SiC wafer fabrication and device processing, focusing on the etching process, its significance, and specific applications.

Etching Process:

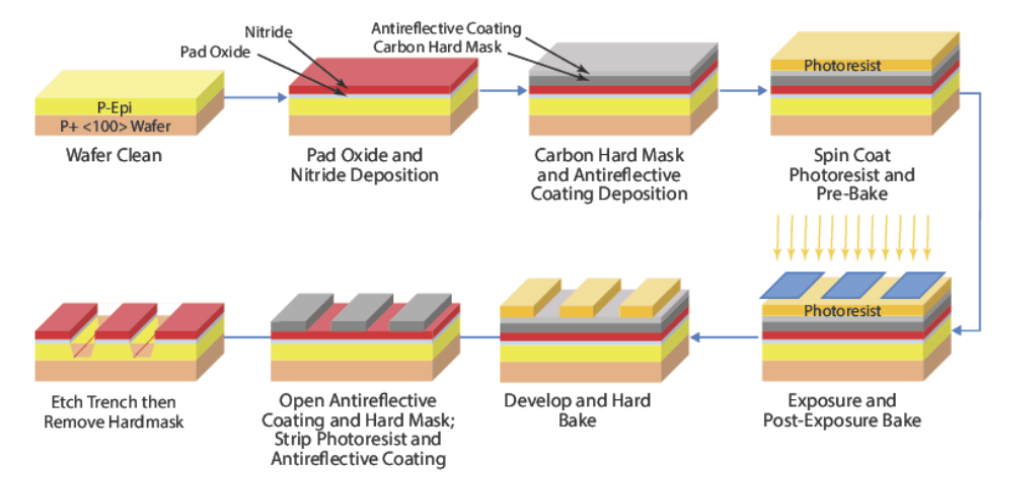

Etching is a process of selectively removing material from the surface of a substrate to achieve specific structures, patterns, or shapes. In the etching process of SiC wafers, common methods include dry etching and wet etching. Dry etching is mainly achieved through plasma etching and electron beam etching, while wet etching is primarily accomplished through acid or alkaline solution etching.

Importance of Etching:

Etching plays a critical role in SiC wafer fabrication and device processing. Firstly, etching is used for patterning and defining structures on the surface of SiC wafers, such as manufacturing microscale and nanoscale circuit patterns, conductive paths, channels, junctions, etc. Secondly, etching helps to sharpen the edges of SiC devices, improving their performance and stability. Additionally, etching can alter the surface properties of SiC wafers, such as increasing surface roughness, changing surface energy, producing nanostructures, etc., thereby affecting the electrical, optical, and interfacial properties of devices. Lastly, etching offers enhanced selectivity, enabling selective removal of specific areas of SiC material to achieve complex structures.

Applications of Etching:

Etching has various applications in SiC wafer fabrication and device processing. It is used for fabricating microscale and nanoscale device structures, such as microelectronic devices, power devices, optoelectronic devices, etc. Additionally, etching is employed for patterning and defining structures on the surface of SiC wafers, including circuit patterns, conductive paths, channels, junctions, etc. Moreover, etching is utilized to sharpen the edges of SiC devices, enhancing their performance and stability. Furthermore, etching can alter the surface properties of SiC wafers, expanding the application areas and functionalities of SiC devices. Lastly, etching offers enhanced selectivity, enabling selective removal of specific areas of SiC material to achieve complex structures.

Conclusion:

In conclusion, etching technology plays a crucial role in SiC wafer fabrication and device processing, enabling precise fabrication, structure definition, and performance optimization of SiC devices. By selecting appropriate etching methods and parameters, precise fabrication and functional control of SiC wafers can be achieved, thereby driving the development and application of SiC devices.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...