Abstract

Silicon carbide (SiC) substrates are critical for high-power and high-frequency electronic devices, as well as optoelectronic applications. However, the presence of defects, often referred to as "birthmarks," can significantly impact their performance and reliability. This paper explores the causes of these defects and their effects on the mechanical, electrical, thermal, and optical properties of SiC substrates. The necessity of stringent control over the production processes to minimize these defects is also discussed.

Introduction

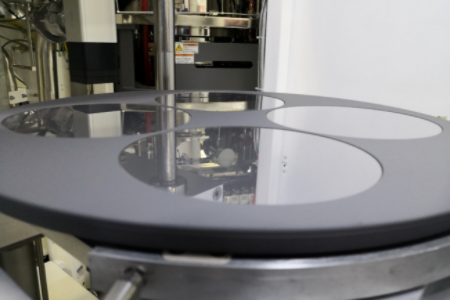

Silicon carbide (SiC) is a highly valued material in the semiconductor industry due to its excellent thermal conductivity, high breakdown electric field, and wide bandgap. Despite these advantageous properties, the presence of defects in SiC substrates, colloquially known as "birthmarks," can adversely affect their performance. These defects arise from various stages of the production process, including crystal growth, doping, and subsequent handling and processing.

Causes of Defects in SiC Substrates

1. Crystal Growth Defects: During the growth of SiC crystals, common defects such as dislocations, stacking faults, grain boundaries, and vacancies can occur. These defects result from inconsistencies in atomic arrangements within the crystal lattice.

2. Impurities: Impurities like nitrogen (N), oxygen (O), and various metal contaminants can be incorporated into the SiC crystal lattice during growth. These impurities can alter the electrical and optical properties of the material, creating visible spots or colorations on the substrate.

3. Thermal and Mechanical Stress: The process of cooling the SiC crystal after growth can induce thermal stress, leading to micro-cracks and other defects. Mechanical stress during cutting, grinding, and polishing can also introduce surface or subsurface damage.

4. Processing Damages: Defects can be introduced during wafer processing steps such as sawing, lapping, and chemical mechanical polishing. Poorly controlled processing conditions can lead to surface scratches, cracks, and other forms of damage.

5. Epitaxial Growth Issues: In the epitaxial layer growth process, defects in the underlying SiC substrate can propagate into the epitaxial layers, adversely affecting their quality. Variations in growth temperature and gas flow can also introduce defects.

Effects of Defects on SiC Substrate Performance

1. Mechanical Strength: Defects such as micro-cracks and dislocations can significantly reduce the mechanical strength of SiC substrates, making them more susceptible to fracture during processing and operation.

2. Electrical Properties: The presence of impurities and crystal defects can alter carrier concentration and mobility, affecting the electrical performance of SiC-based devices. This can lead to increased on-resistance, higher leakage currents, and reduced device efficiency.

3. Thermal Conductivity: Defects can scatter phonons, reducing the thermal conductivity of SiC. In high-power devices, this can lead to inadequate heat dissipation, resulting in overheating and reduced reliability.

4. Optical Properties: For optoelectronic applications, defects can impact the absorption and emission characteristics of SiC. This is particularly critical in devices such as LEDs and laser diodes, where optical efficiency is paramount.

5. Epitaxial Layer Quality: Defects in the substrate can propagate into the epitaxial layers, affecting the uniformity and quality of the grown layers. This can degrade the performance of the devices fabricated on these layers.

6. Manufacturing Yield: High defect densities can reduce the yield of functional devices, increasing production costs. Defects can render entire wafers unusable, leading to significant material and financial losses.

Mitigation Strategies

To mitigate the impact of defects on SiC substrates, several strategies can be employed:

Improved Crystal Growth Techniques: Techniques such as High Temperature Chemical Vapor Deposition (HTCVD) and Physical Vapor Transport (PVT) can produce higher quality crystals with fewer defects.

Rigorous Impurity Control: Maintaining a clean growth environment and using high-purity source materials can minimize the incorporation of impurities.

Stress Management: Controlled cooling and the use of stress-relief techniques can reduce thermal stress-induced defects.

Advanced Processing Methods: Utilizing precise and well-controlled wafer processing techniques can minimize damage introduced during cutting, grinding, and polishing.

Epitaxial Growth Optimization: Fine-tuning growth conditions and using defect-selective etching can improve the quality of epitaxial layers.

Conclusion

Defects in SiC substrates, commonly referred to as "birthmarks," have a significant impact on their mechanical, electrical, thermal, and optical properties. These defects arise from various stages of production, including crystal growth, impurity incorporation, thermal and mechanical stress, and processing damage. Understanding the origins and effects of these defects is crucial for improving the quality and performance of SiC-based devices. By employing advanced production techniques and stringent process controls, it is possible to minimize the presence of these defects, thereby enhancing the reliability and efficiency of SiC substrates in various applications.

This paper highlights the importance of addressing and mitigating defects in SiC substrates to ensure their optimal performance in high-power, high-frequency, and optoelectronic devices.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...