When it comes to silicon carbide (SiC) wafer materials, the 4H-HPSI type of silicon carbide stands out for its exceptional material characteristics and its wide range of applications in the semiconductor industry. As a third-generation semiconductor materials expert, JXT Technology Co., Ltd. (https://www.jxtwafer.com/) will provide a detailed overview of the characteristics, advantages, and applications of 4H-HPSI silicon carbide.

1.Properties of 4H-HPSI Silicon Carbide wafer

Crystal Structure:Hexagonal

Lattice Constant: a=3.076 Å c=10.053 Å

Density: 3.21 g/cm3

Melting point: 2830℃

Mohs Hardness:≈9.2 mohs

Dielectric Constant: c~9.66

Band Gap: 3.23 eV

Breakdown Electrical Field: 3-5×106V/cm

Thermal Conductivity: a~4.9 W/cm·K@298K , c~3.9 W/cm·K@298K

Thermal Expansion: 4-5×10-6/K

Refractive Index@750nm:no = 2.61 ne = 2.66

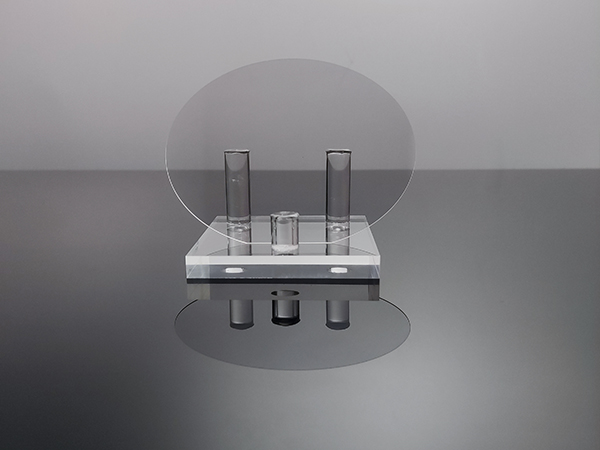

2. Specification of 4H-HPSI Silicon Carbide wafer

Diameter:50.8mm/100mm/150mm

Thickness: 500μm

Surface Orientation: On Axis:{0001} ± 0.2°

Primary Flat Orientation: Parallel to <11-20>±1°

Primary Flat Length: 16mm/32.5mm/47.5mm/Notch

Resistivity: ≥1E7Ω.cm

Front Surface Finish: Si-Face:CMP,Ra<0.5nm

Back Surface Finish: C-Face:Optical Polish,Ra<1nm

Laser Mark: Back side(C-Face)

TTV: 10-20μm

BOW: 25-60μm

WARP:30-80μm

3. Applications of 4H-HPSI Silicon Carbide Wafer

Power Electronics: 4H-HPSI silicon carbide is widely used in manufacturing power switch devices for grid applications, electric vehicle chargers, and industrial power applications, thanks to its high-temperature performance and high-voltage tolerance.

Communication: In high-frequency applications, 4H-HPSI silicon carbide is employed to manufacture radio frequency power amplifiers, antennas, microwave equipment, and more, providing higher efficiency and performance.

Optoelectronics: 4H-HPSI silicon carbide finds application in manufacturing photodiodes and laser diodes, meeting the requirements of communication, laser radar, and medical equipment, among other fields.

Sensors: Given its exceptional performance, 4H-HPSI silicon carbide has significant potential in high-temperature sensor manufacturing for industrial and automotive applications.

In summary, 4H-HPSI silicon carbide is a versatile material, distinguished by its unique material characteristics, outstanding advantages, and its wide range of applications in the semiconductor industry. Whether in high-temperature, high-voltage electronic devices, communication, or sensor applications, this material provides robust support for innovation in various fields.

Gallium nitride (GaN) is a key wide-bandgap semiconductor material widely used in optoelectronics and high-pow...

GaN-on-Si LED epitaxial wafers are essential material platforms for high-performance optoelectronic devices. B...

In industries such as precision manufacturing, optics, semiconductors, and aerospace, surface roughness is a c...