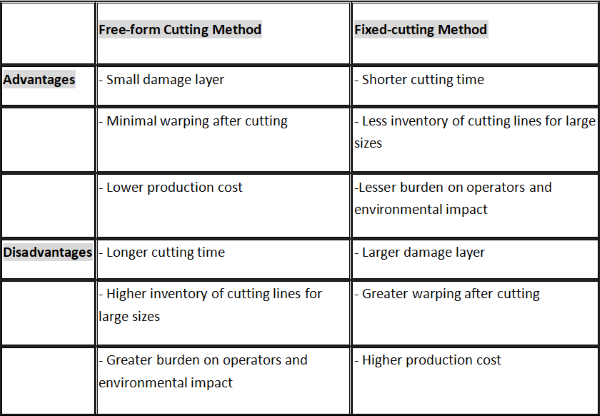

In the semiconductor industry, silicon carbide substrates (SIC substrates) play a crucial role, and the processing method directly impacts production efficiency and product quality. In the processing of silicon carbide substrates, free-form and fixed-cutting are two common methods. In this article, we will provide a detailed comparison of these two processing methods in terms of productivity and processing quality.

Productivity Comparison

Free-form Cutting:

Free-form cutting is known for its high efficiency in production. In this method, each substrate is fixed in a fixture during cutting, allowing for simultaneous cutting operations on large batches. This high efficiency makes free-form cutting particularly effective in batch production scenarios.

Fixed-cutting:

In contrast, fixed-cutting reduces the frequency of mechanical movements. With the substrate remaining relatively stationary during processing, fixed-cutting reduces the wear of cutting tools and saves time by minimizing tool movement. However, compared to free-form cutting, fixed-cutting may require longer processing times as each substrate needs precise positioning and fixing before cutting.

Quality Comparison

Free-form Cutting:

Free-form cutting can provide high processing precision. By accurately controlling the position and angle of each substrate, free-form cutting ensures accuracy and consistency in cutting. However, frequent movement of cutting tools may introduce additional mechanical vibrations, affecting surface quality.

Fixed-cutting:

Fixed-cutting reduces the impact of mechanical vibrations on processing quality. The relative stability of the substrate helps improve surface quality and processing precision. However, fixed-cutting may be limited by the fixed position of substrates, making it challenging to process shapes with higher complexity effectively.

Conclusion

In conclusion, the choice between free-form and fixed-cutting should be based on specific processing requirements and production conditions. If high production efficiency and precision are needed, free-form cutting may be more suitable. On the other hand, if higher processing quality is required, and some reduction in production efficiency can be accepted, fixed-cutting may be more appropriate. In practical applications, a flexible combination of these two cutting methods can be employed to maximize production needs.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...