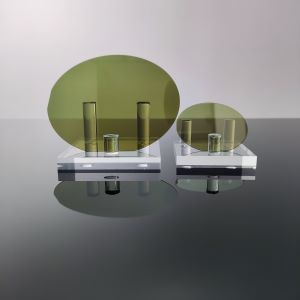

In today's semiconductor technology domain, silicon carbide (SiC) epitaxial growth technology has garnered significant attention due to its continuous advancements in crystal quality, growth rate, and application scope, offering vast prospects and potential applications for SiC epi wafers in the future semiconductor industry.

Firstly, with ongoing improvements in manufacturing processes and enhancements in control technologies, the crystal quality of SiC epitaxial growth has seen remarkable advancements. By optimizing growth conditions and controlling impurity levels, the density of crystal defects has been significantly reduced, laying a solid foundation for improved device performance and reliability of SiC epi wafers.

Secondly, manufacturers are striving to enhance the growth rate and uniformity of SiC epitaxial growth to meet the demands of large-scale production of SiC epi wafers. Through innovations in reactor design and gas-phase transport systems, higher growth rates and improved uniformity have been achieved, providing robust support for large-scale industrial applications of SiC epi wafers.

Furthermore, the application of poly-SiC technology has introduced new avenues for the production of large-scale, low-cost SiC epitaxial films, which can be used for SiC epi wafers. Poly-SiC technology has been successfully applied in photovoltaic cells and solar energy systems, offering crucial support for the development of renewable energy applications utilizing SiC epi wafers.

The development of heterogeneous junction devices is also a significant application direction for SiC epitaxial growth technology, especially for SiC epi wafers. Utilizing SiC epitaxial growth technology, devices such as SiC/GaN heterogeneous junction laser diodes have been produced, demonstrating immense potential in high-power and high-frequency applications for SiC epi wafers.

Lastly, the utilization of SiC epitaxial growth technology for the production of nanostructured materials, such as SiC nanowire arrays, presents new opportunities and potential for the development of flexible electronic devices and sensors, including those based on SiC epi wafers. Through precise control of growth conditions and crystal growth directions, precise control and fabrication of nanostructured materials suitable for SiC epi wafers have been achieved.

In conclusion, the continuous advancements in SiC epitaxial growth technology in terms of crystal quality, growth rate, and application scope offer new opportunities and challenges for the development and widespread use of SiC epi wafers in the semiconductor industry. In future research and practice, SiC epitaxial growth technology will continue to play a vital role in driving the continuous advancement of semiconductor technology and the expansion of application domains for SiC epi wafers.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...