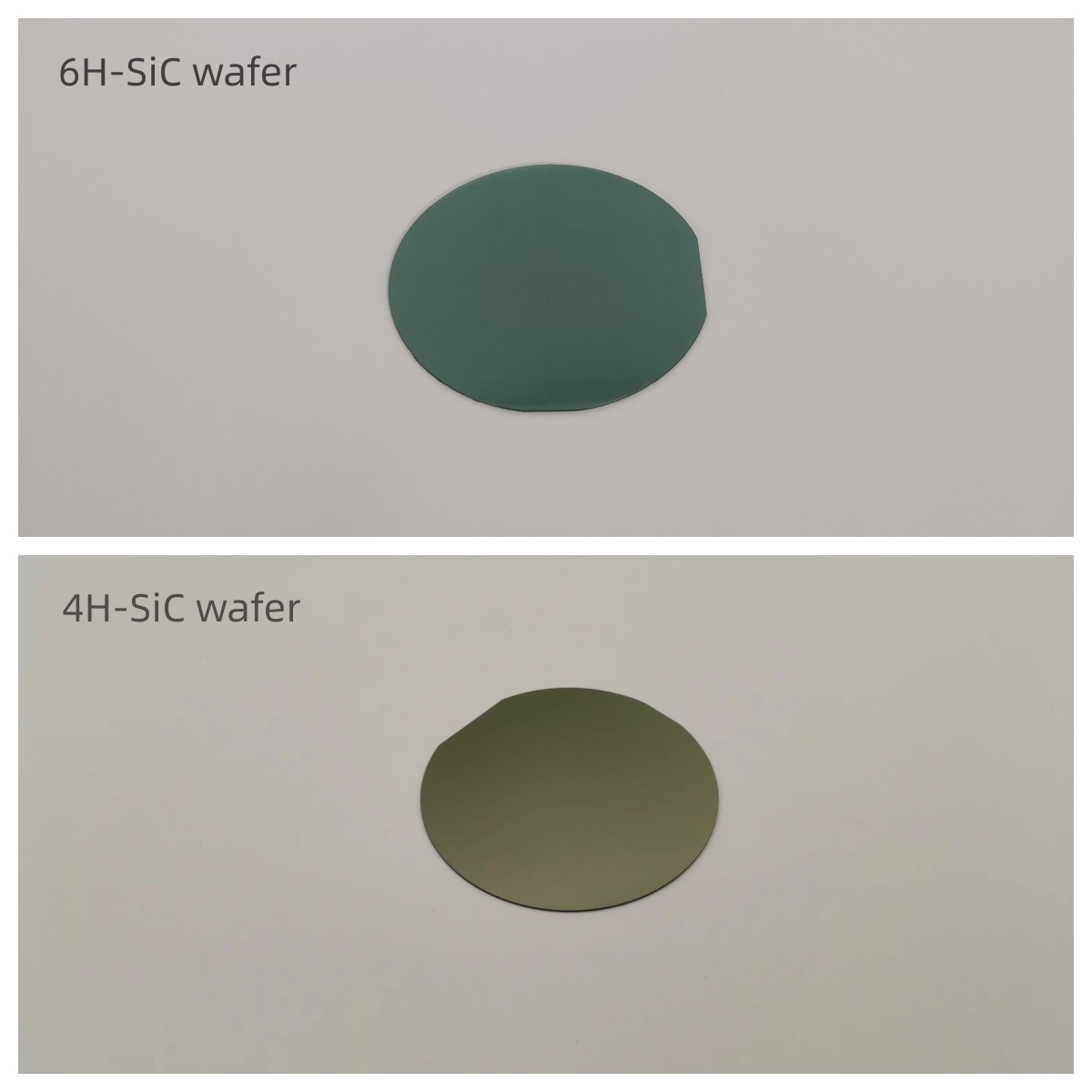

Silicon carbide (SiC) is a popular semiconductor material known for its excellent mechanical, thermal, and electrical properties. It is widely used in the production of various electronic devices, including diodes, MOSFETs, and power electronics. SiC substrate wafer comes in different crystal structures, including 6H and 4H. While both structures are popular, they have their own advantages and disadvantages.

The 6H and 4H SiC structures differ in their stacking sequence and crystal symmetry. The 6H SiC structure has a hexagonal lattice with alternating layers of silicon and carbon atoms arranged in a 6-fold symmetry. On the other hand, the 4H SiC structure has a tetrahedral crystal symmetry with alternating layers of silicon and carbon atoms arranged in a 4-fold symmetry. The differences in crystal symmetry and stacking sequence give each structure its own unique set of properties and characteristics.

6H SiC has a higher thermal conductivity than 4H SiC, which makes it ideal for high-temperature applications. It also has a lower intrinsic carrier concentration, which means that it can handle higher electric fields without experiencing breakdown. However, it has a lower electron mobility, which makes it less suitable for high-frequency applications.

4H SiC, on the other hand, has a higher electron mobility than 6H SiC, which makes it ideal for high-frequency applications. It also has a wider bandgap than 6H SiC, which means that it can operate at higher temperatures and handle higher voltages. However, it has a lower thermal conductivity than 6H SiC, which makes it less suitable for high-temperature applications.

In terms of processing, 6H SiC is easier to grow and process than 4H SiC. It has a higher growth rate and a lower defect density, which makes it more cost-effective for large-scale production. 4H SiC, on the other hand, is more difficult to grow and process due to its higher defect density and lower growth rate. However, its superior electrical properties make it ideal for high-performance applications.

In summary, the choice between 6H and 4H SiC depends on the specific requirements of the application. 6H SiC is ideal for high-temperature applications that require high thermal conductivity, while 4H SiC is ideal for high-frequency applications that require high electron mobility. While 6H SiC is easier to grow and process, 4H SiC has superior electrical properties that make it suitable for high-performance applications.

Gallium nitride (GaN) is a key wide-bandgap semiconductor material widely used in optoelectronics and high-pow...

GaN-on-Si LED epitaxial wafers are essential material platforms for high-performance optoelectronic devices. B...

In industries such as precision manufacturing, optics, semiconductors, and aerospace, surface roughness is a c...