Introduction

Gallium nitride possesses excellent physical and chemical properties, such as a wide bandgap, high breakdown electric field, and high thermal conductivity, making it highly promising for electronic and optoelectronic devices. However, high dislocation densities commonly found in GaN single crystals can significantly affect device performance, reducing the material's photoelectric conversion efficiency and electron mobility. Therefore, exploring methods for growing high-quality GaN single crystals and controlling dislocations is of great importance. The ammonothermal method has become a key technique for producing GaN single crystals due to its unique advantages.

Growth of GaN Single Crystals by the Ammonothermal Method

The ammonothermal method primarily involves the reaction of metallic gallium and a nitrogen source under high temperature and high pressure in an ammonia atmosphere to form GaN single crystals. The main steps of this method include:

1. Preparation of Reactants: High-purity metallic gallium and nitrogen sources (such as lithium nitride or magnesium nitride) are selected.

2. Reactor Design: The high-pressure reactor must withstand high temperatures and pressures, typically made from precious metals or high-strength alloys.

3. Control of Growth Conditions: Under a high-pressure ammonia environment, the temperature is usually controlled between 600-800°C, the pressure between 0.1-0.5 GPa, and the reaction time ranges from several hours to several tens of hours.

4. Crystal Pulling and Cooling: Crystals grow slowly under an appropriate temperature gradient, and controlling the cooling rate helps avoid stress-induced dislocations.

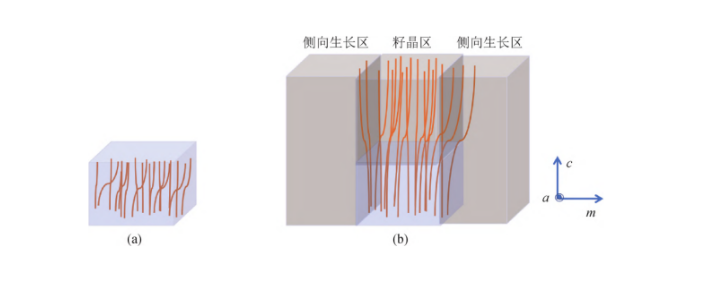

Formation and Evolution of Dislocations

During the growth of GaN single crystals by the ammonothermal method, dislocation formation and evolution are complex processes influenced mainly by the following factors: Please Click the Profile about GaN Wafers

1. Temperature Gradient and Stress: The temperature gradient during crystal growth induces thermal stress, leading to dislocation generation and propagation. Optimizing the temperature gradient can reduce the impact of thermal stress, thereby lowering dislocation density.

2. Growth Rate: The growth rate significantly affects dislocation formation. Excessive growth rates increase internal defects in the crystal, raising dislocation density. Slowing the growth rate can effectively reduce dislocation formation.

3. Impurity Effects: The presence of impurities during growth induces dislocations. Using high-purity raw materials and maintaining a clean growth environment can significantly reduce impurity-induced dislocations.

Optimization Strategies to Reduce Dislocation Density

1. Optimizing Temperature and Pressure Conditions: Experimental research can identify the optimal temperature and pressure conditions to control crystal growth quality and reduce dislocation formation.

2. Introducing Buffer Layers: Buffer layers on the substrate can effectively mitigate stress concentration, reducing dislocation density.

3. Post-Growth Treatment Techniques: Techniques such as annealing can repair some dislocations, improving crystal quality.

Conclusion

The ammonothermal method is an effective approach for producing high-quality GaN single crystals. By carefully controlling growth conditions and optimizing growth processes, dislocation density in GaN single crystals can be significantly reduced. Future research should further optimize process parameters and explore new methods to enhance GaN single crystal quality, providing a robust material foundation for high-performance electronic and optoelectronic devices.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...