As technology rapidly advances, the performance demands on electronic materials continue to escalate, and traditional silicon-based materials are gradually falling short of meeting the needs of emerging applications. Against this backdrop, gallium oxide (Ga₂O₃) has garnered significant attention in both research and industry as a wide-bandgap semiconductor material, thanks to its outstanding properties.

Fundamental Properties of Gallium Oxide

Gallium oxide (Ga₂O₃, CAS No. 12024-21-4) is a versatile functional material with five different crystallographic phases: α, β, γ, δ, and ε. Among these, β-Ga₂O₃ is the most stable phase, crystallizing in the monoclinic system with lattice constants a=12.12 Å, b=3.03 Å, and c=5.80 Å, and belongs to the C2/m symmetry group. Due to its stability and superior material characteristics, β-Ga₂O₃ is the most extensively studied and applied phase of gallium oxide.

Gallium oxide possesses a wide bandgap of approximately 4.8 eV, allowing it to operate effectively under high-voltage and high-temperature conditions. With a density of 5.88 g/cm³, Ga₂O₃ is insoluble in water but soluble in acidic and alkaline metal hydroxide solutions. Its high breakdown field and excellent electron mobility make it highly promising for high-voltage power device applications.

Unique Physical Characteristics

Gallium oxide exhibits several unique physical properties that distinguish it in the semiconductor domain. Theoretically, Ga₂O₃ has an electron mobility of up to 300 cm²/Vs, a breakdown voltage of up to 8 MV/cm, and a static dielectric constant of 10. These properties suggest that Ga₂O₃ can withstand high voltages and deliver higher efficiency under high-power conditions.

However, Ga₂O₃ has a relatively low thermal conductivity at room temperature, with anisotropic values reaching a maximum of only 0.27 W/cm×K. Additionally, its thermal expansion coefficient is 3.37×10⁻⁶ K⁻¹, and it has a melting point of 1900 °C. These thermodynamic properties indicate that Ga₂O₃ maintains high stability under high-temperature conditions, making it suitable for electronic devices operating in extreme environments.

Broad Application Potential

Due to its excellent material properties, gallium oxide has been widely applied across various high-tech fields. As a critical functional material, Ga₂O₃ is used not only in phosphors or luminescent materials but also plays a role in catalysis. Furthermore, Ga₂O₃ can serve as a semiconductor insulating barrier, making it suitable for gas sensors, solar cells, photodetectors, and power devices.

In the fields of power electronics and solar-blind detection, Ga₂O₃ exhibits tremendous potential. For example, its high breakdown field enables Ga₂O₃-based power devices to operate at higher voltages while maintaining smaller device sizes and higher energy efficiency. This makes Ga₂O₃ a key candidate for high-voltage power devices such as efficient switches and rectifiers.

Development and Fabrication of Gallium Oxide Substrates

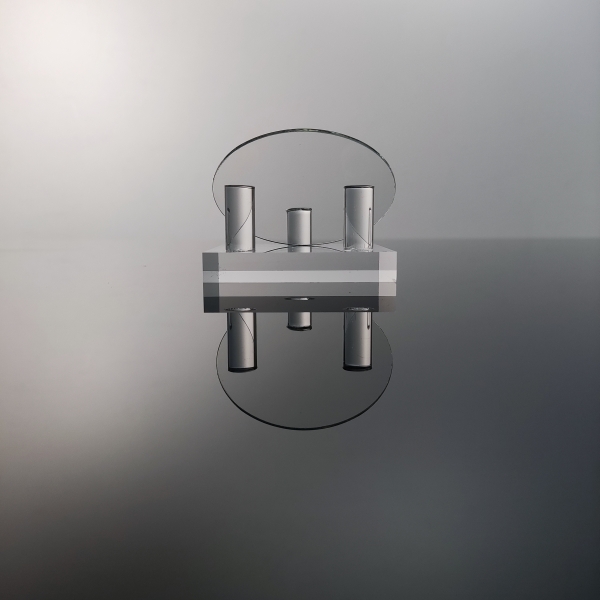

Currently, gallium oxide substrates can be grown using various methods, including melt growth (Czochralski method), liquid phase epitaxy (LPE), and chemical vapor deposition (CVD). These techniques have enabled Ga₂O₃ wafer sizes to reach 2-inch, 4-inch, and even 6-inch diameters, laying a solid foundation for its application in large-scale integrated circuits.

Compared to other wide-bandgap semiconductor materials such as gallium nitride (GaN) and silicon carbide (SiC), Ga₂O₃ substrates are relatively easier to fabricate and come at a lower cost. As a result, Ga₂O₃ is viewed as a critical foundational material for next-generation wide-bandgap semiconductor devices, with the potential for widespread application across various fields.

Conclusion

Gallium oxide (Ga₂O₃) is rapidly emerging as a vital material in the power electronics and optoelectronics sectors due to its exceptional wide bandgap, high breakdown field, excellent electron mobility, and thermal stability. As substrate fabrication technologies continue to evolve, Ga₂O₃ is poised to play an increasingly significant role in future high-performance electronic devices, providing robust support for technological advancement and industrial upgrading.

Related product links

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...