Dislocations are a significant factor affecting the quality and performance of 4H-SiC (Silicon Carbide) single crystals. Understanding the types of dislocations, their causes, and control methods is crucial for improving the quality of 4H-SiC single crystals.

Types of Dislocations

The common types of dislocations in the growth process of 4H-SiC single crystals include screw dislocations, edge dislocations, basal plane dislocations (BPDs), and stacking faults.

1. Screw Dislocations:

Screw dislocations have dislocation lines parallel to the growth direction of the crystal. They usually form in the early stages of growth due to thermal stress or interface stress.

2. Edge Dislocations:

Edge dislocations have dislocation lines perpendicular to the direction of slip. They are typically caused by uneven growth conditions or stress introduced by impurities.

3. Basal Plane Dislocations (BPDs):

BPDs are primarily parallel to the (0001) basal plane of the SiC crystal. These dislocations significantly impact the electrical properties of SiC crystals, particularly affecting the breakdown voltage of power devices.

4. Stacking Faults:

Stacking faults occur due to misalignment of atomic layers during the growth process, typically appearing on the (0001) plane of the SiC crystal, leading to local structural mismatches.

Causes of Dislocations

1. Temperature Gradient and Thermal Stress:

Uneven temperature distribution during growth can lead to thermal stress, resulting in the formation of dislocations. For instance, high-temperature areas may cause material expansion, while low-temperature areas may lead to contraction, creating stress concentration zones.

2. Impurities and Defects:

The introduction of impurity atoms disrupts the uniformity of the SiC crystal, generating local stress that induces dislocations.

3. Growth Rate and Conditions:

Excessive growth rates or unstable growth conditions increase the defect density within the crystal. For example, rapid cooling can cause sudden contraction of the crystal structure, forming dislocations.

4. Substrate Quality:

Defects and inhomogeneities in the substrate material can be transferred to the growing SiC single crystal, leading to the formation of dislocations.

Control Methods

To reduce dislocations in 4H-SiC single crystals, several control methods are employed:

1. Optimizing Growth Conditions:

Controlling the growth temperature and temperature gradient ensures uniformity and stability during the crystal growth process.

2. Using High-Purity Materials:

Utilizing high-purity Si and C materials minimizes the introduction of impurities.

3. Slow Cooling:

Adopting a slow and uniform cooling rate reduces the generation of thermal stress.

4. Improving Substrate Quality:

Using low-defect-density substrates can significantly reduce the initial dislocation density, thereby improving the quality of the single crystal.

5. Defect Control Techniques:

Employing specific defect control techniques, such as the "screw dislocation conversion" method in Chemical Vapor Deposition (CVD), can effectively reduce dislocation density.

In summary, understanding and controlling the types and causes of dislocations during the growth of 4H-SiC single crystals, along with implementing appropriate control measures, can significantly enhance the quality of 4H-SiC single crystals. This, in turn, improves their performance in electronic devices, highlighting the importance of these materials in high-performance electronic applications.

Related product links

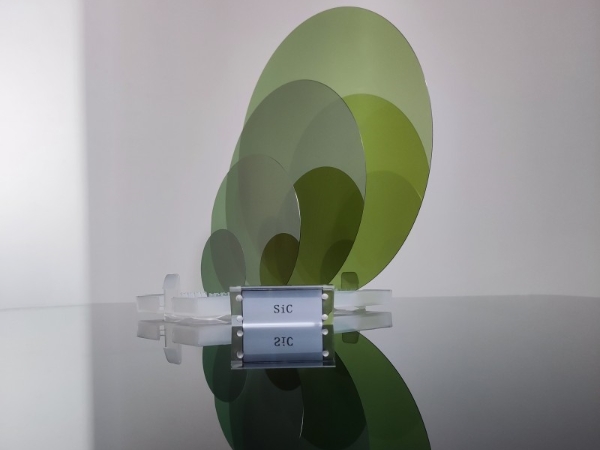

Silicon Carbide (SiC) Substrate

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...