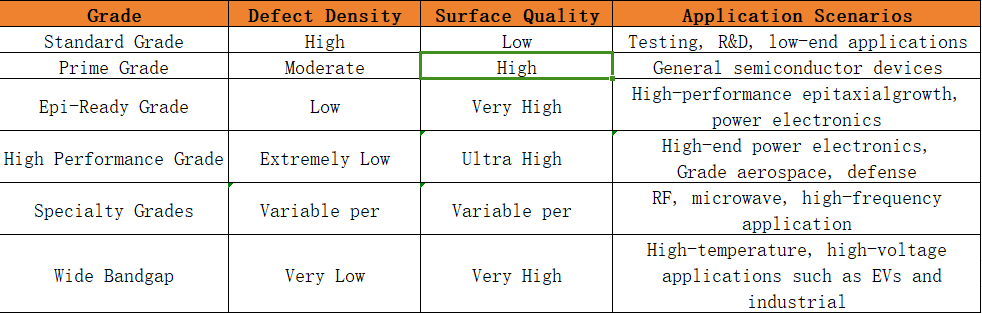

Silicon Carbide (SiC) substrates are classified based on their quality and characteristics, which determine their suitability for various applications and market value. The following are the primary grades of SiC substrates:

1. Standard Grade

This is the most basic grade of SiC substrates, typically used for applications with lower quality requirements or for testing and research purposes. Characteristics include:

Size: Generally smaller, commonly 2-inch or 4-inch in diameter.

Defect Density: High, with numerous dislocations and micropipes.

Surface Treatment: Surface may have many defects and low polish quality, unsuitable for high-quality epitaxial growth.

Applications: Mainly used for testing, R&D, prototype development, and educational experiments.

2. Prime Grade

Prime Grade SiC substrates offer higher quality, suitable for general semiconductor device fabrication with good electrical and mechanical properties. Characteristics include:

Size: Commonly 4-inch and 6-inch.

Defect Density: Moderate levels of dislocations and micropipes.

Surface Treatment: Better polish quality, suitable for general epitaxial growth needs.

Applications: Used for power electronic devices and other applications requiring a certain level of substrate quality.

3. Epi-Ready Grade

Epi-Ready Grade SiC substrates have extremely high surface quality, specifically designed for epitaxial growth (e.g., GaN and SiC epitaxy). Characteristics include:

Size: Typically 6-inch and 8-inch, to meet high-volume production needs.

Defect Density: Very low dislocation and micropipe density.

Surface Treatment: Ultra-high polish with no significant surface defects, ideal for high-quality epitaxial layer growth.

Applications: Used for high-performance, high-reliability power electronic devices, RF, and microwave devices.

4. High Performance Grade

This grade of SiC substrates offers the best quality and characteristics, meeting the most demanding application requirements. Characteristics include:

Size: Usually 6-inch or larger.

Defect Density: Extremely low, approaching defect-free ideal conditions.

Surface Treatment: Polished and cleaned to the highest standards, fully suitable for advanced epitaxial growth and high-performance device fabrication.

Applications: High-end power electronics, RF devices, high-frequency, and high-power applications, especially in aerospace, defense, and high-end industrial applications.

5. Specialty Grades

These SiC substrates are tailored for specific applications, requiring specially designed characteristics such as:

Ultra-High Resistivity: Suitable for RF and microwave devices.

Specific Conductivity Types: Like semi-insulating types, used for high-frequency and low-noise applications.

High Thermal Conductivity: For high-power applications requiring efficient heat dissipation.

Special Crystal Orientation: Custom orientations such as 4H-SiC or 6H-SiC for specific needs.

6. Wide Bandgap Application Grade

This grade is designed for wide bandgap device applications, meeting the requirements for operation in high-temperature and high-voltage environments. Characteristics include:

Size and Thickness: Typically larger and thicker to support the efficient operation of wide bandgap devices.

Defect Control: Strict control of defect density to maximize device performance.

Surface Treatment: Very high surface treatment standards, suitable for wide bandgap material epitaxial growth.

Applications: Used in electric vehicles, solar inverters, and industrial power management systems.

These classifications help users select the most suitable SiC substrate based on specific application needs, ensuring optimal performance and cost efficiency.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...