With the rapid advancement of wide bandgap semiconductor materials, gallium oxide (Ga₂O₃) has demonstrated significant potential in power electronic devices, ultraviolet detectors, and optoelectronic applications due to its ultra-wide bandgap (4.8–5.3 eV), high breakdown electric field (~8 MV/cm), and excellent optoelectronic properties. However, given its high melting point (~1800°C), the fabrication of high-quality, large-sized Ga₂O₃ single crystals remains a critical research focus.

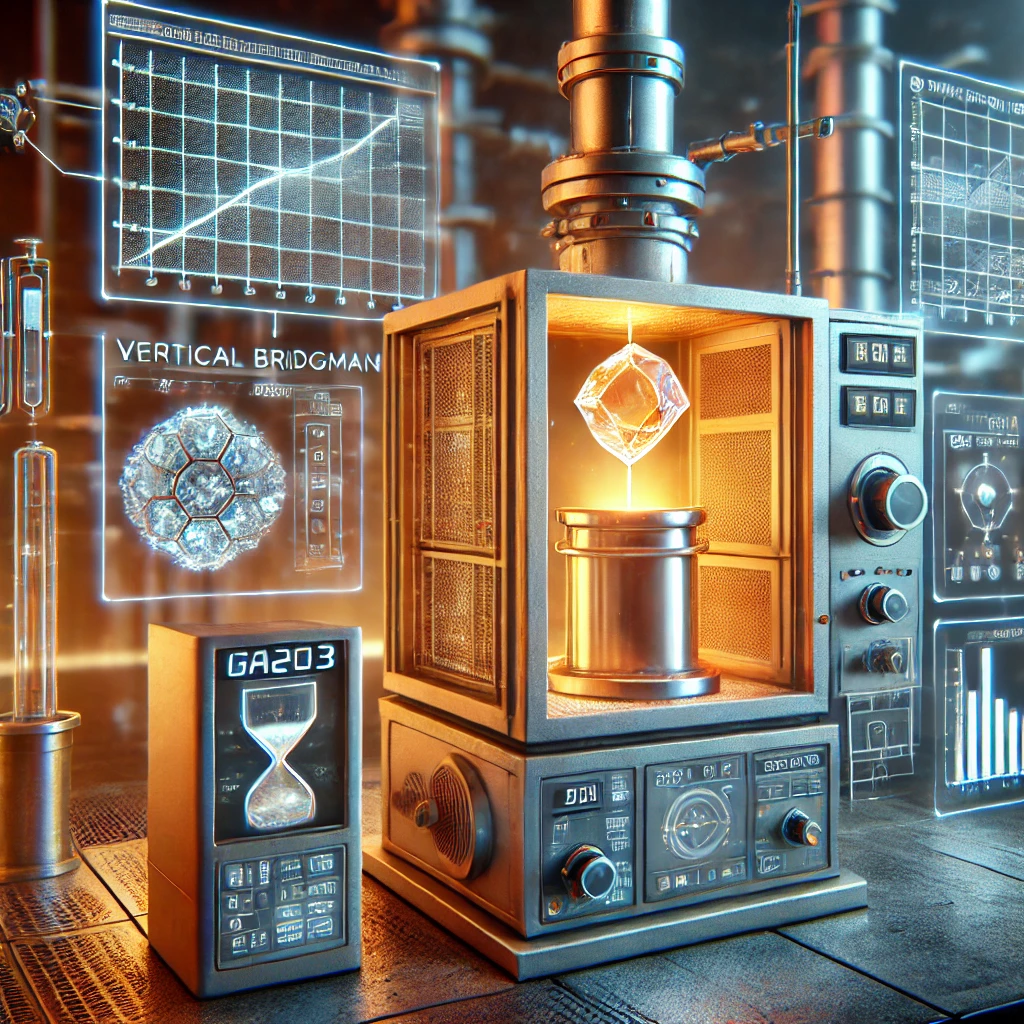

Among various crystal growth techniques, the Vertical Bridgman (VB) method is recognized as an effective approach for Ga₂O₃ single crystal growth due to its process stability, suitability for large-scale crystal growth, and relatively simple equipment requirements. This article provides a systematic overview of the VB method, including its principles, process flow, advantages, challenges, and its application prospects in semiconductor devices.

1. Principles and Process of the VB Method

1.1 Principles of the VB Method

The Vertical Bridgman (VB) method is a crystal growth technique based on controlled temperature gradients that regulate the solidification of the melt. The core concept involves gradually lowering the crucible or precisely controlling the temperature field to allow the melt to solidify progressively from the bottom, ultimately forming a high-quality single crystal. This method is widely used for growing oxide semiconductor materials such as gallium oxide (Ga₂O₃), aluminum oxide (Al₂O₃), and cadmium telluride (CdTe).

1.2 Process Flow of Ga₂O₃ Crystal Growth via the VB Method

(1) Preparation of High-Purity Raw Materials

- High-purity β-Ga₂O₃ powder is selected and subjected to high-temperature sintering to remove impurities and enhance material purity.

- An oxygen partial pressure regulator (e.g., O₂ atmosphere) is employed to optimize the composition uniformity of the Ga₂O₃ melt.

(2) Crucible Selection and Temperature Field Design

- Due to the high melting point of Ga₂O₃ (~1800°C), crucibles made of platinum (Pt) or aluminum oxide (Al₂O₃) are commonly used to ensure excellent heat resistance and corrosion resistance.

- Induction heating or resistance heating is utilized to provide a stable temperature field, with a controlled temperature gradient of 50–100°C/cm to ensure uniform crystal growth.

(3) Melting and Crystallization Process

- The Ga₂O₃ raw material is completely melted at a high temperature (>1800°C) to ensure melt homogeneity.

- The crucible descent rate (typically 0.5–2 mm/h) is precisely controlled to allow the melt to solidify progressively from the bottom, forming a high-quality β-Ga₂O₃ single crystal.

- A moderate cooling rate is employed to prevent thermal stress-induced cracking, thus improving the yield of defect-free crystals.

(4) Crystal Extraction and Post-Processing

- After gradual cooling, the Ga₂O₃ single crystal is extracted and subjected to X-ray diffraction (XRD), Raman spectroscopy, and infrared spectroscopy to assess crystal quality.

- Further slicing, grinding, and polishing are performed to prepare Ga₂O₃ wafers suitable for device applications.

2. Advantages and Challenges of the VB Method for Ga₂O₃ Growth

2.1 Key Advantages

- Suitable for large-sized crystal growth: The VB method enables the production of Ga₂O₃ single crystals larger than 2 inches, meeting industrial application demands.

- Stable process and high crystal quality: With precise temperature control and optimized crystallization rates, the VB method can produce high-quality, low-defect single crystals.

- Relatively simple equipment, suitable for industrialization: Compared to other melt-based methods (e.g., Floating Zone (FZ) method), the VB process is more mature and suitable for large-scale industrial production.

2.2 Major Challenges

- High melting point poses equipment challenges: The elevated melting point of Ga₂O₃ (~1800°C) necessitates high-temperature-resistant crucibles and stable heating systems, increasing production costs.

- Thermal stress-induced cracking: Due to its high thermal expansion coefficient, Ga₂O₃ crystals are prone to thermal stress cracks during cooling, requiring optimized cooling rates and temperature field designs.

- Impurity control and crystal uniformity optimization: Ga₂O₃ is susceptible to oxygen partial pressure variations at high temperatures, potentially leading to impurity segregation, necessitating precise atmospheric control.

3. Application Prospects of VB-Grown Ga₂O₃ Crystals

Due to its ultra-wide bandgap, high breakdown field, and superior optoelectronic properties, Ga₂O₃ single crystals have promising applications in several advanced electronic and optoelectronic fields:

(1) Power Electronic Devices

- High-voltage switches and power MOSFETs: The high breakdown field (~8 MV/cm) of β-Ga₂O₃ makes it ideal for fabricating high-power, high-efficiency power semiconductor devices, applicable to electric vehicles, smart grids, and renewable energy conversion.

- RF power amplifiers (RF PAs): The high power density of Ga₂O₃ enables its potential use in 5G communication and radar systems.

(2) Deep Ultraviolet Detectors

- With its wide optical transparency range (200–5000 nm), β-Ga₂O₃ is highly suitable for ultraviolet photodetectors and deep ultraviolet photodiodes (UV PDs), widely used in space exploration, environmental monitoring, and biomedical detection.

(3) Field-Effect Transistors (FETs)

- Ga₂O₃ is ideal for high-power, high-frequency field-effect transistors (HEMTs), with applications in millimeter-wave communications and high-frequency amplifiers.

(4) Optoelectronics and Laser Devices

- In deep-ultraviolet light sources and laser devices, Ga₂O₃ single crystals can serve as substrate materials for short-wavelength lasers, demonstrating significant application potential.

4. Conclusion

The Vertical Bridgman (VB) method has proven to be an effective technique for growing high-quality Ga₂O₃ single crystals, owing to its low process complexity, excellent crystallization quality, and suitability for large-scale crystal fabrication. While challenges such as high-temperature equipment limitations, thermal stress control, and impurity management remain, ongoing advancements in crystal growth technology and increasing industrial demand are expected to drive further progress in this field.

Future research directions will focus on optimizing temperature field design, reducing crystal defects, and improving growth efficiency, promoting the widespread application of Ga₂O₃ materials in next-generation semiconductor technologies.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...