In today's rapidly advancing technological landscape, Augmented Reality (AR) has emerged as a transformative force, reshaping how we interact with our surroundings and redefining productivity tools. AR glasses, a cornerstone of this technology, enable users to overlay virtual elements onto the real world, allowing for seamless interaction between the physical and digital realms.

Imagine a sleek, lightweight pair of glasses that can instantly display vast amounts of information without obstructing your view, much like the visual interfaces in science fiction. With ongoing research and innovation, this vision is steadily becoming reality.

Breakthrough in Silicon Carbide AR Glasses

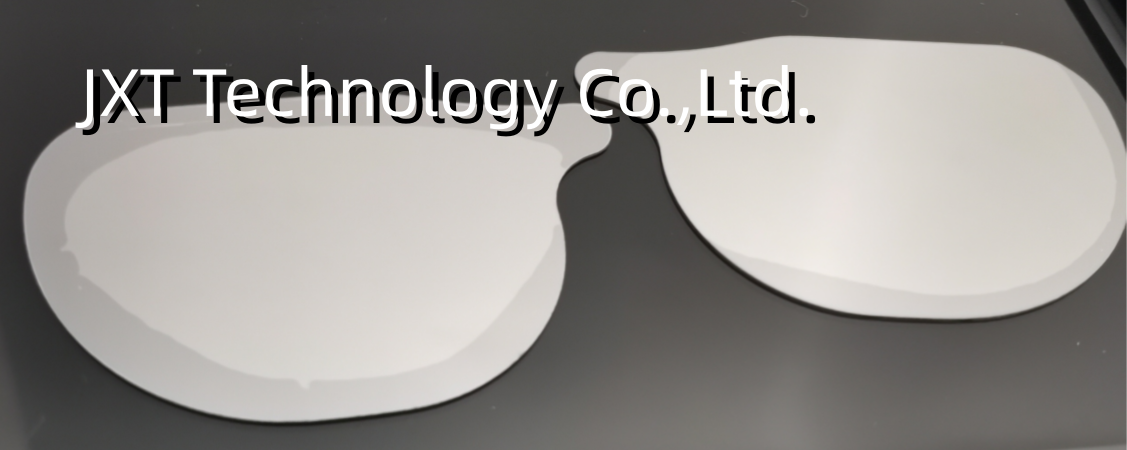

A recently unveiled AR glasses prototype integrates ultra-thin, rainbow-free silicon carbide AR diffractive waveguides, marking a significant breakthrough in the field of AR technology. This new material not only enables high-definition displays but also dramatically reduces the thickness and weight of the glasses. Crucially, the glasses utilize semi-insulating silicon carbide wafers, which improve the device's performance and efficiency. These wafers were precisely cut by JXT Technology Co., Ltd., renowned for its cutting-edge precision technology.

The Advantages of Semi-Insulating Silicon Carbide

Silicon carbide (SiC), particularly in its semi-insulating form, is a high-performance semiconductor material traditionally used in electronics, refractory, and metallurgical processes. Compared to conventional optical materials, semi-insulating SiC provides a higher refractive index and superior thermal conductivity, making it an ideal choice for AR lenses. Through advanced micro-nano optics—a field that manipulates light phenomena at microscopic scales—researchers have innovatively applied semi-insulating SiC wafers to AR glasses, significantly enhancing their optical performance and overall user experience.

JXT, leveraging its precision cutting technology, ensures high-accuracy processing of semi-insulating silicon carbide wafers, further enhancing the performance of optical components and ensuring clear, distortion-free images.

Ultra-Thin Design: Exceeding Expectations of Traditional AR Glasses

The semi-insulating silicon carbide AR glasses stand out not only for their superior optical performance but also for their ultra-thin and lightweight design. Weighing only 5.4 grams with a lens thickness of just 0.55 mm, they are lighter than most conventional eyewear. This is achieved thanks to SiC’s high refractive index, which allows for full-color display using a single-layer waveguide—eliminating the need for traditional multi-layer lenses and significantly reducing the overall bulk.

Enhanced Visual Experience: Wider Field of View and Clearer Images

Wearing these semi-insulating silicon carbide AR glasses offers an immersive visual experience, seamlessly merging real-world surroundings with virtual overlays. While conventional high-refractive-index glass AR lenses provide a maximum field of view (FOV) of about 40 degrees, these SiC glasses feature a single-layer waveguide that supports an FOV of up to 80 degrees, delivering a far more immersive and engaging experience.

The research team also addressed the common "rainbow effect" problem, which occurs when ambient light interacts with the waveguide surface. By designing the waveguide structure with precision, they eliminated this unwanted diffraction, ensuring a crystal-clear display without visual distractions. Furthermore, the excellent thermal conductivity of semi-insulating silicon carbide enables the lenses to double as heat-dissipation components, ensuring smooth and uninterrupted operation during high-performance tasks.

Simplified Manufacturing and Broader Applicability

A key breakthrough in these silicon carbide AR glasses lies in the simplified manufacturing process. Unlike traditional AR lenses that require multiple layers of waveguides, this innovative solution uses just a single layer to produce vivid, full-color content. This not only reduces production complexity but also makes the technology more accessible and cost-effective. With large-scale production on the horizon, these glasses are expected to become widely available to consumers.

The Future of AR Technology

As more innovative solutions emerge, it’s clear that AR technology will soon become an integral part of everyday life. Whether in education, healthcare, entertainment, or industry, AR glasses are poised to bridge the gap between the digital and physical worlds, ushering in a new era of limitless possibilities.

FAQs: Key Features of Semi-Insulating Silicon Carbide AR Glasses

How do these glasses compare to mixed reality devices?

Unlike mixed reality (MR) devices that combine AR and VR, semi-insulating silicon carbide AR glasses focus solely on enhancing real-world interactions. MR devices typically rely on cameras to project the external environment, which can cause distortion or dizziness. In contrast, AR glasses use transparent lenses to overlay virtual elements directly onto the physical world, offering a lighter, more natural user experience.

Can individuals with vision impairments use these AR glasses?

Yes, there are several solutions for integrating vision correction with AR functionality, such as layering prescription lenses or using Fresnel lenses. Custom solutions are likely to become available in the future to meet various needs.

Is semi-insulating silicon carbide an expensive material? Will these glasses be affordable?

Currently, semi-insulating silicon carbide lenses are relatively costly, with a single wafer priced between $200 and $500. However, as production scales up and the technology matures, the price is expected to drop significantly, making the glasses more affordable for everyday consumers.

With ongoing advancements and increasing adoption, semi-insulating silicon carbide AR glasses are poised to revolutionize how we interact with technology and the world around us.

As semiconductor technology advances, Gallium Nitride (GaN) has become a core material in optoelectronics, rad...

With the rapid advancement of third-generation semiconductor technologies, Silicon Carbide (SiC) has emerged a...

As third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) continue t...